Milk adulteration: what laboratory testing methods are available?

Milk adulteration is a threat to the quality and conformity of dairy products. What methods can be used to detect these frauds quickly, reliably and ...

Since 2005, CIRAM and its laboratories have been verifying and certifying the biobased content of all industrial biopolymers and packaging using carbon-14 (or radiocarbon) analysis.

Contact our teams

Regulations governing bioplastics and biosourced packaging have become increasingly stringent in recent years, in response to environmental challenges and ecological transition objectives.

In France, the law on energy transition for green growth has imposed a minimum proportion of biosourced material in single-use plastic bags since 2017. This proportion is gradually being increased, rising from 30% to 60% from January 1, 2025.

At the same time, companies are increasingly required to trace and certify the composition of their materials, particularly in the food packaging sector. These regulatory changes are forcing manufacturers to scientifically justify the composition of their products to guarantee compliance and anticipate quality audits.

Contact our teams

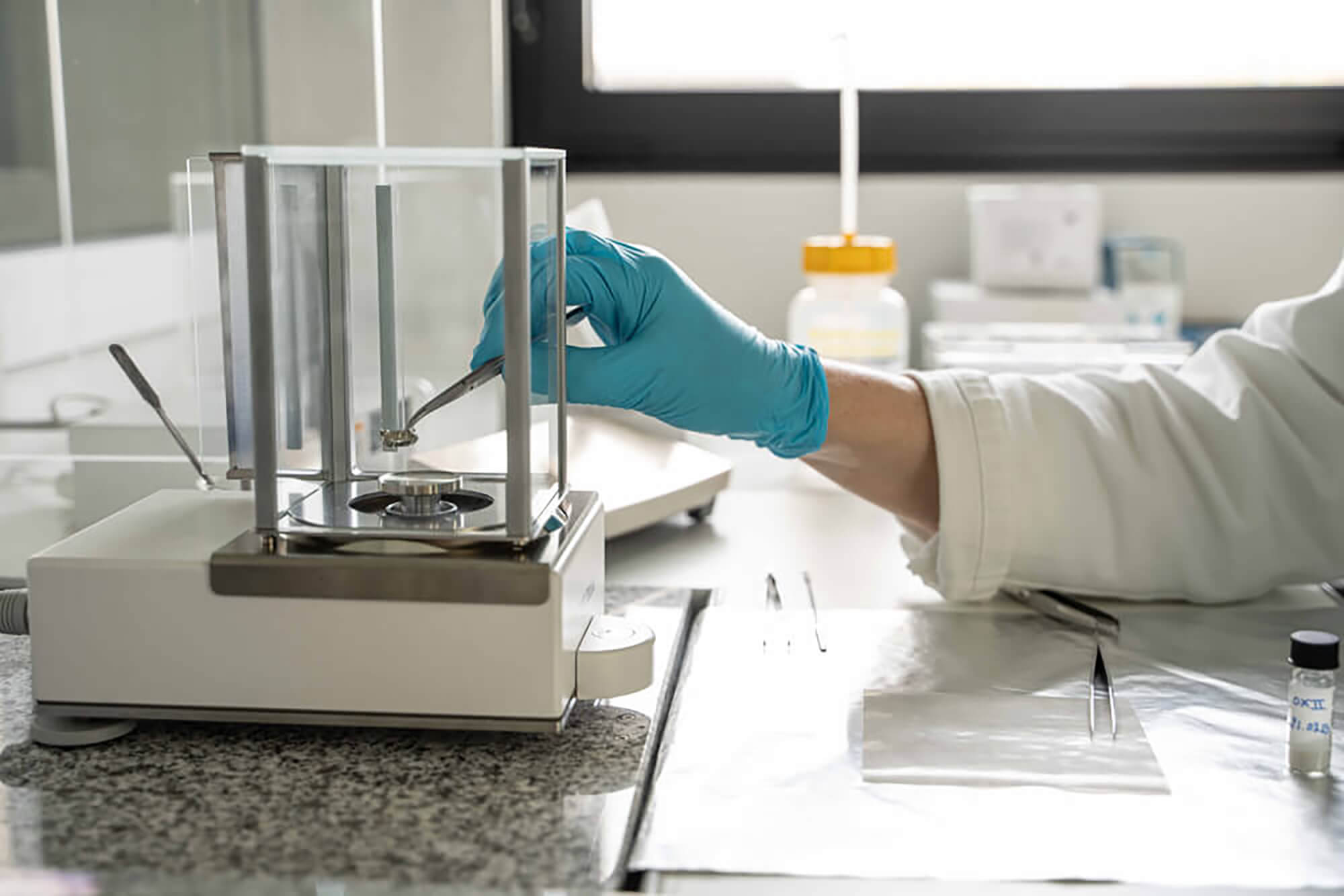

Radiocarbon analysis is the reference method for determining the biobased carbon content in polymeric materials. Our engineers use gas pedal mass spectrometry (AMS) to measure the fraction of biogenic carbon present in a sample with high precision, in compliance with international standards such as ASTM D6866 and ISO 16620-2.

This method is suitable for a wide range of materials, including biopolymers, thermosetting resins, polyolefins (such as polypropylene) and plant-based fiber composites.

For cardboard-based packaging - intrinsically derived from biomass - the radiocarbon analysis enables us to assess the influence of non-biobased components such as inks, varnishes, pigments or surface treatments. This scientific approach guarantees a rigorous, objective assessment of the actual biobased content of packaging, essential for environmental claims, certifications or eco-design initiatives.

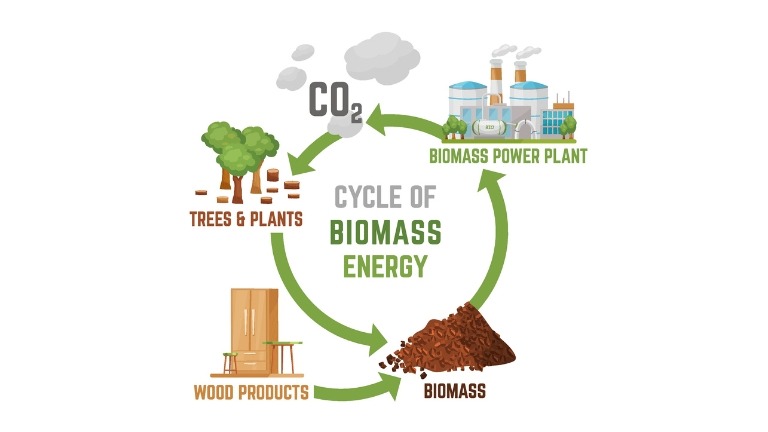

Request a quoteBiobased polymers play a key role in the decarbonization of industry. Unlike conventional plastics derived from fossil resources, bioplastics are made from renewable raw materials such as corn starch, sugarcane or vegetable oils. These materials capture atmospheric CO₂ during their growth, making it possible to partially offset emissions linked to production and processing.

When used on a large scale, these materials can significantly reduce greenhouse gas emissions over the entire product life cycle, particularly in the packaging, agri-food, cosmetics and logistics sectors.

The use of biosourced plastics enables manufacturers to diversify their sources of supply and limit their exposure to fluctuations in oil markets. This independence from fossil resources is strategic in a context of energy tension and transition to a circular economy.

By replacing all or part of their conventional resins with biobased alternatives, companies can anticipate future regulatory and environmental constraints, while enhancing their brand image in the eyes of stakeholders sensitive to sustainability issues.

Radiocarbon analysis is an essential lever for obtaining official labels promoting the biobased content of plastics and packaging. These certifications provide third-party, reliable and measurable recognition of manufacturers' environmental commitment. CIRAM has been accredited by TUV AUSTRIA since 2024. You can therefore use CIRAM's carbon 14 measurement service to obtain the OK Biobased label.

Among the most frequently used labels:

These labels not only certify the quality of your plastics and packaging, but also demonstrate your concern for the environment and climate change.

With over two decades' experience in the analysis of organic materials, CIRAM is a trusted scientific partner for manufacturers committed to the transition to bio-based solutions. Our laboratories carry out over 5,000 carbon-14 analyses every year, using rigorous protocols that comply with the most demanding international standards (ASTM D6866, ISO 16620-2, EN 16640).

We mobilize cutting-edge technologies, in particular gas pedal mass spectrometry (AMS), which enables ultra-sensitive measurement of biogenic carbon content, even in complex matrices or those with low biobased content. This precision is essential to guarantee reliable results, which are indispensable for obtaining certifications.

Take advantage of the expertise of Europe's leader in radiocarbon analysis and request your study on our website.

Contact our teamsCIRAM uses radiocarbon analysis by gas pedal mass spectrometry (AMS). This method measures the content of carbon-14, an isotope characteristic of biobased materials, to precisely quantify the proportion of biobased carbon in a material.

CIRAM analyses comply with ASTM D6866 and ISO 16620-2 standards, guaranteeing reliable and recognized results for the certification of industrial biopolymers and packaging. CIRAM is accredited by TUV AUSTRIA.

CIRAM analyzes a wide range of materials, including: biopolymers (PLA, PHA, PBS, bio-PE, bio-PET, etc.), biosourced thermosetting resins, partially biosourced polyolefins (e.g. polypropylene), natural fiber/polymer matrix composites, and complex cartons and packaging, including with inks, varnishes or specific treatments.

Results are available within 10 working days.

Simply contact us via our website or by telephone to obtain a quotation and arrange for samples to be sent to our laboratory.

Milk adulteration is a threat to the quality and conformity of dairy products. What methods can be used to detect these frauds quickly, reliably and ...

Test the naturalness of your flavors and dietary supplements using radiocarbon and stable isotopes. Carbon 14 and stable isotopes allow...

Stable isotope measurements play a key role in the quality control and traceability of industrial materials. But how can you be sure of the reliability of your results? By entrusting your...

Increasing demands for traceability and sustainability make ISCC Plus certification a strategic asset for manufacturers involved in biobased products. Find out more...

EN ISO 21644 is an essential standard for ensuring the compliance and traceability of solid recovered fuels (SRF). But how can you be sure that your materials comply ...

Honey adulteration is a growing threat to the industry, compromising quality, conformity and traceability. Addition of exogenous sugars, falsification of origin, purity tests ins...